A fabric to be proud of: the best towel, made with tenacity and craftsmanship

MIKI HOUSE boasts a variety of items that have all been loved throughout the years.

Our sweatshirt is one of them. Many of you may know our signature sweatshirt with the large logo print on the back. Similarly, many people love MIKI HOUSE's towels.

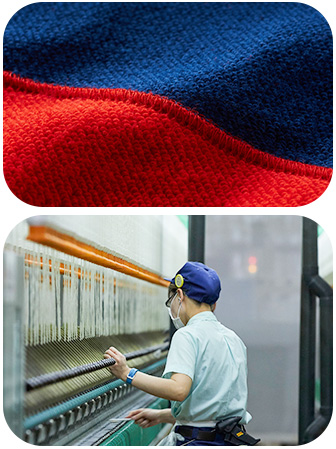

Cutting and sewing are not the only things that make a great product. The quality of the raw materials, thread and fabric are also critical factors to make comfortable and high-usability products.

In this article, let us introduce the story of a "spinning man" who has been working on thread and fabric for over 40 years. He created the French Terry fabric that is the fabric of the MIKI HOUSE sweatshirt, and American Sea Island Cotton, the “dream cotton” used only for the best towels.